Water treatment is a critical process for ensuring clean and safe water for consumption, industrial processes, and environmental sustainability. Among the many chemicals used for water purification, Polyaluminium Chloride (PAC) has gained significant attention for its effectiveness and efficiency in coagulation and flocculation processes. This article explores the role of PAC in water treatment, its applications, and the benefits it provides in comparison to other conventional coagulants.

What is Polyaluminium Chloride (PAC)?

Polyaluminium Chloride (PAC) is a water-soluble polymer that is produced by polymerizing aluminium chloride (AlCl₃) and aluminium hydroxide (Al(OH)₃). PAC is a coagulant and flocculant used in water treatment for removing impurities, suspended solids, and contaminants, especially in municipal drinking water and wastewater treatment systems.

Unlike traditional coagulants like alum (aluminum sulfate), PAC is known for its superior efficiency and faster settling time in water treatment processes. It has a high charge density, making it particularly effective at destabilizing suspended particles and forming larger flocs, which can then be removed through sedimentation or filtration.

How Does PAC Work in Water Treatment?

The primary function of PAC in water treatment is coagulation and flocculation.

Coagulation: In the first stage, PAC is added to raw water containing suspended particles, organic matter, and contaminants. The positively charged PAC molecules neutralize the negative charges of the particles, causing them to clump together into smaller aggregates or "microflocs."

Flocculation: Once coagulation is complete, the water is gently stirred, allowing the smaller microflocs to merge and grow into larger flocs. These flocs are large enough to settle at the bottom of the treatment tank, where they can be removed via sedimentation.

Filtration: After sedimentation, the treated water is passed through filters to remove any remaining fine particles before being discharged or sent to consumers.

Key Benefits of PAC in Water Treatment

Higher Efficiency and Faster Settling

PAC has a higher charge density compared to traditional coagulants like alum, leading to more effective particle aggregation. This results in faster settling and more efficient removal of suspended solids.

Improved Water Quality

The use of PAC significantly improves the quality of treated water by reducing turbidity, removing organic and inorganic contaminants, and enhancing the clarity of the water. It can also remove harmful microorganisms like bacteria and viruses.

Lower Dosage Requirements

PAC is more effective at lower doses than alum, reducing the chemical consumption and operational costs in the treatment plant. This is especially beneficial in treating water with high turbidity or organic content.

Reduced Sludge Production

The coagulation process with PAC generates less sludge than alum-based treatments, making it easier and more cost-effective to handle and dispose of the sludge. This is an important consideration for wastewater treatment facilities.

Versatility in Various Water Types

PAC is effective in treating various types of water, including drinking water, industrial water, and wastewater. Its versatility allows it to be used in a wide range of applications, such as municipal water treatment, industrial effluent treatment, and even in food and beverage industries.

Less pH Sensitivity

PAC performs effectively over a broader pH range than alum, making it suitable for use in water with varying chemical compositions. This adaptability ensures better performance in a range of water treatment scenarios.

Applications of PAC in Water Treatment

Municipal Drinking Water Treatment

PAC is widely used in municipal drinking water treatment plants for coagulation and flocculation. Its high efficiency and quick settling properties help in producing safe, clear, and potable water.

Wastewater Treatment

In wastewater treatment plants, PAC is employed to remove organic and inorganic contaminants. It plays a vital role in the clarification of effluent, making it safe for discharge into the environment or reuse.

Industrial Water Treatment

Industrial plants use PAC for treating process water, cooling water, and other wastewater streams. It effectively removes heavy metals, oils, fats, and other industrial pollutants, ensuring that water complies with environmental discharge standards.

Tertiary Treatment of Water

In some cases, PAC is used in tertiary treatment, which is the final stage of wastewater treatment. It helps remove remaining suspended solids and fine particles, further improving water quality before release.

Food and Beverage Industry

The food and beverage sector uses PAC in the treatment of water used for manufacturing, ensuring high-quality water that meets safety standards for production and consumption.

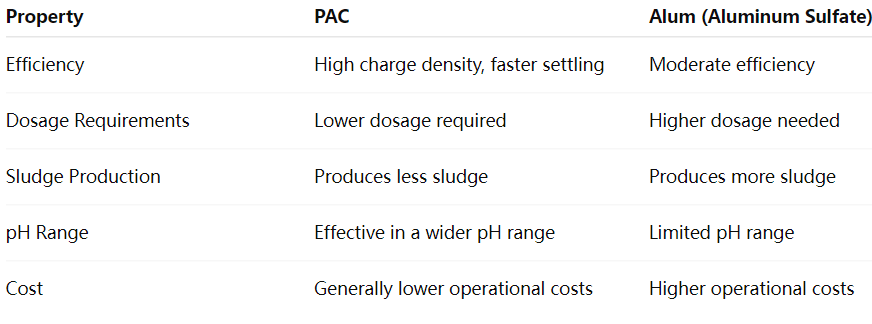

Comparison Between PAC and Traditional Coagulants

Environmental and Economic Considerations

The use of PAC in water treatment is not only beneficial in terms of performance but also in environmental and economic terms. PAC’s lower sludge production helps minimize disposal costs and environmental impact. The reduced chemical dosage translates into cost savings, which makes PAC an economically viable option for water treatment facilities. Additionally, PAC’s superior efficiency reduces the overall energy consumption of the treatment process, contributing to environmental sustainability.

Challenges and Limitations of PAC

Despite its many benefits, there are a few challenges associated with PAC:

Cost of Procurement: While PAC is generally more cost-effective in the long run, the initial procurement cost may be higher than that of alum. However, this can be offset by lower chemical dosages and reduced sludge disposal costs.

Storage and Handling: PAC needs to be stored properly to maintain its effectiveness. It must be kept in a dry and cool environment to prevent it from degrading over time.

Floc Formation Sensitivity: In some cases, PAC may produce flocs that are too fine, which can make the filtration process more difficult. Proper optimization of PAC dosage is required to ensure the formation of flocs that are large enough to be removed efficiently.

Conclusion

Polyaluminium Chloride (PAC) plays a vital role in modern water treatment processes due to its high efficiency, reduced sludge production, and cost-effectiveness. Its ability to treat a wide range of water types, including municipal drinking water, industrial effluents, and wastewater, makes it a versatile and preferred choice in water treatment plants worldwide.

While PAC presents numerous benefits, including faster settling times, lower chemical requirements, and improved water quality, its adoption requires proper handling and dosage optimization. When applied correctly, PAC ensures that water treatment facilities can meet stringent water quality standards while reducing operational costs and environmental impact.

In conclusion, PAC represents a significant advancement in water treatment technology, offering a sustainable and efficient solution to meet the growing demand for clean water worldwide.

En

En

عربى

عربى 中文简体

中文简体