1. The use of phosphorus-free corrosion and scale inhibitors in circulating water should be combined with the water quality of the circulating cooling water system to determine the dosage, typically controlled between 10 and 30 ppm.

2. The product should be added continuously.

3. The product has good compatibility and can be used with oxidizing biocides, non-oxidizing biocides, and stripping agents.

4. The phosphorus-free corrosion and scale inhibitor is widely used in power generation, petrochemicals, steel, pharmaceuticals, oil and gas fields, and other industrial sectors.

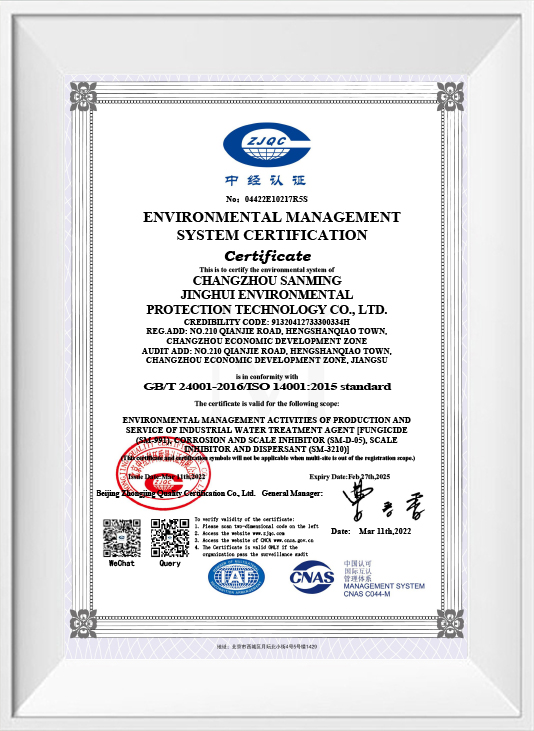

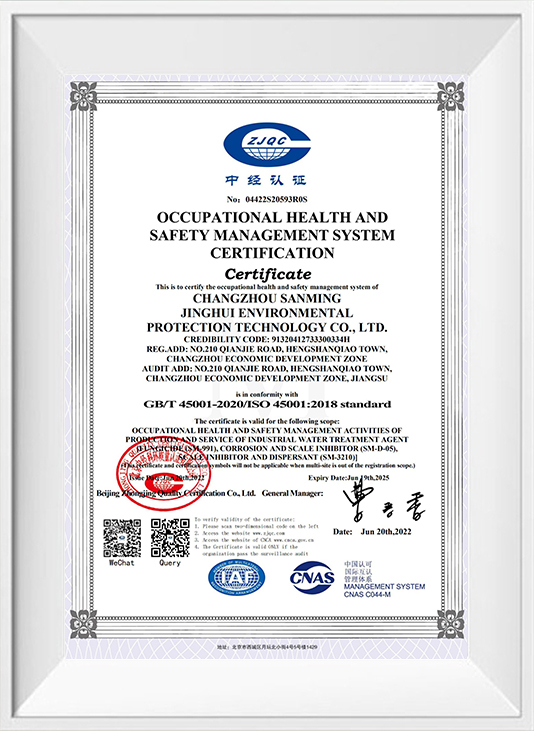

Changzhou Sanming Jinghui's main business is the production and sales of water treatment chemicals, the design and construction of industrial circulating water systems, circulating water treatment scheme design, technology application, technology transfer, and general contracting services; sewage treatment engineering design, construction, and technology Application, general contracting services. It has made outstanding achievements in circulating water, wastewater treatment, reclaimed water reuse, energy conservation and emission reduction in domestic large and medium-sized petroleum, petrochemical, metallurgy, chemical, fertilizer, coal chemical, electric power and other industrial enterprises, and has a large number of stable employees in various industries. customer base. After more than 30 years of development, the water treatment general contracting technical service model currently has more than 50 customers in the power, steel, chemical industry, etc., serving more than 200 sets of circulating water systems, achieving results, and helping customers save energy, reduce emissions, and stabilize production. Make outstanding contributions. The products now in mass production include: organic phosphonic acids, polycarboxylic acids and sulfonate copolymers, corrosion inhibitors, corrosion and scale inhibitors, cleaning agents, pre-film agents, defoaming agents, bactericidal algaecides , flocculants, oil flocculants and other ten series, with more than 100 product varieties of water treatment chemicals.

Our company produces a variety of customized chemicals that can be used in circulating cooling water systems. Industries involved in circulating water systems: such as cooling water systems in power plants, steel plants, chemicals, petrochemicals, paper mills, waste incineration plants, pharmaceutical plants, and textile printing and dyeing plants. Different industries have different chemical solutions that prevent corrosion and scale formation on metal surfaces in water systems. Traditional corrosion and scale inhibitors usually contain phosphate components, but due to the improvement of environmental protection requirements, more and more companies are turning to the use of phosphorus-free corrosion and scale inhibitors. We produce phosphorus-free and low-phosphorus products with various choices. Pay attention to all The dosage of chemicals should be determined based on the water quality of the circulating cooling water system.

Corrosion/Scale Inhibitor Manufacturers

-

BENEFITS & FEATURES

View MoreProduct Code SM-D-05BW

Appearance Light yellow to brownish yellow transparent uniform liquid

Active matter content, % ≧32.0

pH value (1% aqueous solution) 2~3

Density (20℃), g/cm3 ≧1.10

Total phosphorus content (in terms of PO43-), % ≦2.00

-

BENEFITS & FEATURES

1. The use of this product in circulating water should be combined with the water quality of the circulating cooling water system to determine the dosage, typically controlled between 8 and 20 ppm.

2. The product should be added continuously.

3. The product has good compatibility and can be used with oxidizing biocides, non-oxidizing biocides, and stripping agents.

4. The product is widely used in power generation, petrochemicals, steel, pharmaceuticals, oil and gas fields, and other industrial sectors.

View MoreProduct Code SM-D-05Q

Appearance Light yellow to brownish yellow transparent and homogeneous liquid

Active matter content, % ≧20.0~32.0

pH value (1% aqueous solution) 2~5

Density (20℃), g/cm3 ≧1.10

Total phosphorus content (in terms of PO43-), % 2.00~6.80

-

BENEFITS & FEATURES

1. The scale dispersant for circulating water is widely used in industrial circulating water treatment, chemical cleaning and pre-filming, and oil field water injection treatment systems.

2. For circulating water treatment, the dosage should be determined based on the water quality of the circulating cooling water system, typically controlled between 15 and 40 ppm, with continuous addition. It can be used with corrosion and scale inhibitors, oxidizing biocides, non-oxidizing biocides, and stripping agents.

3. For chemical cleaning and pre-filming of circulating water systems, the dosage should be determined based on the process and water quality, typically controlled between 80 and 100 ppm, with shock dosing.

4. For oil field water injection treatment, the dosage is generally controlled between 10 and 50 mg/L based on the injection water volume, with continuous addition.

View MoreProduct Code SM-3210C

Appearance Colourless to light yellow transparent homogeneous liquid

Active matter content, % ≧30.0

pH value (1% aqueous solution) ≦3.5

Density (20℃), g/cm3 1.05~1.15

-

BENEFITS & FEATURES

1. The use of the scale inhibitor for circulating water should be combined with the water quality of the circulating cooling water system to determine the dosage, typically controlled between 8 and 20 ppm.

2. The product should be added continuously.

3. The product has good compatibility and can be used with oxidizing biocides, non-oxidizing biocides, and stripping agents.

4. The product is widely used in power generation, petrochemicals, steel, pharmaceuticals, oil and gas fields, and other industrial sectors.

View MoreProduct Code SM-D-05A

Appearance Light yellow to brownish yellow transparent and homogeneous liquid

Active matter content, % ≧20.0

pH value (1% aqueous solution) 10.0~12.0

Density (20℃), g/cm3 ≧1.05

Total phosphorus content (in terms of PO43-), % ≦2.00

-

BENEFITS & FEATURES

- The use of circulating water corrosion inhibitor should be combined with the circulating cooling water system water quality, according to the water quality to determine the dosage of the agent, usually the dosage of the agent can be controlled in the range of 5 ~ 15ppm;

- The dosage method of this product is continuous dosage;

- The product has good compatibility and can be used simultaneously with oxidative bactericide, non-oxidative bactericide, stripping agent and other agents;

- The product is widely used in power generation, petrochemical, iron and steel, medicine, oil and gas fields and other industrial fields.

View MoreProduct Code SM-D-05B

Appearance Light yellow to brownish yellow transparent and homogeneous liquid

Active matter content, % ≧20.0

pH value (1% aqueous solution) 2±1.5

Density (20℃), g/cm3 ≧1.05

Total phosphorus content (in terms of PO43-), % ≦0.50

-

BENEFITS & FEATURES

1. The use of closed-loop water corrosion inhibitors should be combined with the water quality of the circulating cooling water system to determine the dosage, typically controlled between 30 and 100 ppm.

2. The product should be added continuously, based on the amount of wastewater discharged.

3. The product has good compatibility and can be used with biocides and other agents.

4. It is widely used in power generation, petrochemicals, steel, pharmaceuticals, oil and gas fields, and other industrial sectors.

View MoreProduct Code SM-D-05C

Appearance Transparent yellow homogeneous liquid

Active matter content, % 20.0~25.0

pH value (1% aqueous solution) 2±1.5

Density (20℃), g/cm3 ≧1.10

Total phosphorus content (in terms of PO43-), % ≦0.50

-

BENEFITS & FEATURES

1. The solid active bromine biocide and algaecide is widely used in industrial circulating water systems, once-through cooling water systems, oilfield injection water, and paper mill wastewater treatment.

2. The product should be added using a shock dosing method.

3. Initial shock dosing should be 20-40 mg/L, followed by shock dosing every 3-7 days at 5-25 mg/L, maintaining a residual chlorine level of 0.1-1.0 mg/L for 2-4 hours.

4. The product has good compatibility and can be used with corrosion and scale inhibitors, non-oxidizing biocides, and stripping agents.

View MoreProduct Code SM-991Y

Appearance White powder or granule

Active matter content, % ≧40.0

pH value (1% aqueous solution) Weak acid

-

BENEFITS & FEATURES

1. The non-oxidizing biocide is commonly used as a biocide in industrial circulating water systems and wastewater treatment, and as a mildew inhibitor in paper and paint production processes.

2. The product should be added using a shock dosing method.

3. When used as a slime stripping agent, the dosage should be controlled between 150-300 mg/L. When used as a biocide, the dosage should be 50-100 mg/L, added every 3-7 days depending on the level of bacteria and algae. It should not be used with chlorine-based oxidizing biocides but can be used with corrosion and scale inhibitors.

View MoreProduct Code SM-991F

Appearance Light yellow or light blue-green transparent and homogeneous liquid

Active matter content, % 1.5~2.5

pH value (1% aqueous solution) 2.0~5.0

Density (20℃), g/cm3 1.02-1.06

-

BENEFITS & FEATURES

1. This product is commonly used as a biocide and algaecide in industrial circulating water systems and as a biocide in oil and gas gathering pipelines.

2. The product should be added using a shock dosing method.

3. When alternating with oxidizing biocides, it should be added 1-2 times per month at a dosage of 50-100 mg/L, calculated based on the system's water volume, and added to the collection tank or rapid flow area of the suction well.

4. The product may produce foam during use, so an appropriate amount of defoamer can be added as needed.

View MoreProduct Code SM-991N

Appearance Light yellow transparent viscous homogeneous liquid

Active matter content, % 25.0~44.0

pH value (1% aqueous solution) 6.0~8.0

-

BENEFITS & FEATURES

1. The antifoam agent is suitable for defoaming treatment in chemical industry, food production, and industrial wastewater and circulating water systems.

2. The product should be added using a shock dosing method.

3. It can be sprayed directly onto the surface of the foaming liquid or pre-mixed into the foaming medium to prevent foam formation, with a typical dosage of 50-100 mg/L.

View MoreProduct Code SM-3210Y

Appearance Milky white uniform viscous liquid

Active matter content, % 10.0~15.0

Density (20℃), g/cm3 0.95~1.10

Since 1991

Changzhou SanmingJingHui Environmental Protection Technology Co., Ltd.

Changzhou SanmingJingHui Environmental Protection Technology Co., Ltd. (formerly Changzhou Sanming Chemical Co., Ltd.) is China scale inhibitor manufacturers and corrosion inhibitor factory, a high-tech, environmentally friendly and energy-saving water treatment agent professional enterprise integrating scientific research and development, production and sales, and technical services. It was founded in 1991.

The company is located in the central area of the Yangtze River Delta, close to the Shanghai-Nanjing Railway and the Beijing-Hangzhou Grand Canal, and is located in Hengshanqiao Town, the middle intersection of the Shanghai-Nanjing Expressway. It is only half an hour away from Changzhou Civil Aviation Airport and has convenient transportation. It has fixed assets of more than 18 million yuan, more than 20 scientific researchers, and 25% of employees have obtained various professional and technical titles.

-

Essential Dosing Strategies for Maximum Efficiency Proper dosing of boiler treatment chemicals is critical for protecting your system while avoiding waste. Mos...

READ MORE -

Essential Water Treatment Chemicals and Their Applications Water treatment relies on specific chemicals to remove contaminants, kill pathogens, and ensure safe...

READ MORE -

Poly aluminium chloride (PAC) is a fast, robust coagulant for water treatment that typically improves turbidity and color removal with steadier pH than alum—whe...

READ MORE -

Most industrial wastewater can be brought into stable compliance by pairing the right coagulant + polymer with tight pH control, then verifying doses with jar t...

READ MORE

More product information about Industrial Circulating Cooling Water System

What are the market trends in industrial cooling water systems?

The market for industrial cooling water systems is rapidly evolving, driven by technological advancements, stricter environmental regulations, and the need for more efficient and sustainable solutions. Industries such as power generation, manufacturing, and petrochemicals are increasingly relying on these systems, leading to significant changes in market trends.

One major trend is the integration of smart technologies. IoT (Internet of Things) and AI (Artificial Intelligence) are transforming cooling water systems by enabling real-time monitoring and predictive maintenance. This not only improves system reliability but also reduces downtime and maintenance costs. Advanced data analytics provide valuable insights, helping operators optimize performance and make informed decisions.

The demand for industrial cooling water systems is also driven by industrial expansion and infrastructure development. New facilities and upgrades to existing ones require modern, efficient cooling systems. There is a growing need for customized solutions that can meet specific industrial needs. Modular systems, which offer flexibility and ease of expansion, are becoming increasingly popular.

Cost considerations are crucial in this market. Manufacturers are focused on offering competitive pricing and analyzing the total cost of ownership, including initial investment, maintenance, and operational costs. This approach ensures that companies get the best value and efficiency from their cooling water systems.

Safety is always a top priority. Enhanced safety features protect personnel and equipment, while operator training and certification ensure that systems are managed safely and efficiently.

The integration of renewable energy sources and combined heat and power (CHP) systems with cooling water systems is another notable trend. These integrations improve energy efficiency and support the shift towards sustainable energy solutions, helping industries reduce their carbon footprint.

Industrial circulating cooling water systems offer several advantages. They effectively manage heat dissipation, ensuring optimal temperature ranges for industrial processes. Their ability to recycle water makes them environmentally friendly and cost-efficient. Advances in treatment technologies prevent scaling, corrosion, and biofouling, extending equipment lifespan and maintaining high operational efficiency.

In summary, the market trends in industrial cooling water systems are characterized by technological innovation, environmental sustainability, and a focus on cost-effectiveness and safety. As industries grow and evolve, the demand for advanced, efficient, and sustainable cooling water systems will continue to rise. Companies that stay attuned to these trends will be well-positioned to meet market demands and capitalize on new opportunities, ensuring a sustainable and prosperous future.

What are the global differences in the adoption and adaptation of cooling water systems?

The adoption and adaptation of cooling water systems vary significantly across the globe, influenced by factors such as climate, industrial needs, regulatory frameworks, technological advancements, and resource availability. Understanding these differences is crucial for industries and policymakers aiming to optimize cooling efficiency and sustainability.

Countries with hot and humid climates, such as India and Brazil, face higher cooling demands, often relying on water-intensive cooling towers. In contrast, arid regions like the Middle East prioritize air-cooled systems to conserve scarce water resources. In temperate regions, such as those in Europe, the choice between water-cooled and air-cooled systems is more balanced, tailored to specific industrial requirements.

Regulatory frameworks also play a pivotal role. The European Union and the USA have stringent environmental regulations that drive the adoption of efficient and eco-friendly cooling technologies, reducing water consumption and thermal pollution. Meanwhile, countries like China are progressively tightening their regulations, pushing industries towards more sustainable practices. In some developing regions, lax regulations may lead to continued use of outdated cooling systems.

Resource availability significantly influences cooling system choices. Water-abundant regions, like Canada and Brazil, may favor water-cooled systems, while water-scarce regions, such as the Middle East, invest in air-cooled alternatives. Economic factors, including the cost of water and energy, further shape these decisions, with higher water costs incentivizing more efficient cooling technologies.

Industrial Circulating Cooling Water Systems offer significant advantages in this context. These systems recirculate water, reducing overall consumption and minimizing thermal discharge into the environment. This not only conserves water but also aligns with environmental sustainability goals, making them particularly attractive in regions with stringent regulations and water scarcity challenges.

In summary, the global differences in the adoption and adaptation of cooling water systems are shaped by a complex interplay of climatic, industrial, regulatory, technological, resource, economic, and environmental factors. As environmental awareness and regulations evolve, there is a clear trend towards more sustainable and efficient cooling technologies worldwide. Industrial Circulating Cooling Water Systems exemplify this shift, offering a viable solution for industries aiming to balance efficiency, cost, and environmental responsibility.

En

En

عربى

عربى 中文简体

中文简体