1. The use of the RO membrane-specific scale inhibitor should be based on water quality and system process conditions to determine the dosage, typically controlled between 3 and 5 ppm, with continuous dosing.

2. The following formula can be used to calculate the volume of SM-3210R standard solution to be added to the dosing tank:U=Q×a×V/1000×ρ×X

Where:

U is the volume of standard solution to be added (L)

Q is the RO feed water flow rate (T/h)

a is the dosage of the agent (ppm, g/T) (standard solution)

V is the effective volume of the dosing tank (L)

ρ is the density of the standard solution (g/L)

X is the actual output of the dosing metering pump (L/h)

1000 is the unit conversion factor (g/kg)

Reverse osmosis water treatment system is an efficient water treatment technology commonly used in drinking water, industrial water, wastewater treatment and other fields. It separates solutes and solvents in water through a semipermeable membrane, thereby removing dissolved solids, ions, macromolecular organic matter, etc., and producing high-purity water. Our company produces and provides a variety of chemicals that can effectively help protect and clean the reverse osmosis membrane, ensure the stable operation of the reverse osmosis system and extend the service life of the membrane.

Slime Stripping Agent Manufacturers

-

BENEFITS & FEATURES

View MoreProduct Code SM-3210 membrane scale inhibitor

Appearance Transparent and homogeneous amber-coloured liquid

Proportion 1.20±0.05

pH value (1% aqueous solution) 1.5~2.5

-

BENEFITS & FEATURES

1. The use of the RO membrane-specific non-oxidizing biocide should be based on water quality and system process conditions to determine the dosage.

2. For routine operation, the dosage is typically controlled between 3 and 8 ppm, with continuous dosing.

3. This product can also be used during equipment cleaning, with a concentration of 20%, alternating between circulation and soaking.

View MoreProduct Code SM-991F-RO

Appearance Pale blue-green transparent homogeneous liquid

Proportion ≧1.02

pH value (1% aqueous solution) ≦7

-

BENEFITS & FEATURES

1. The use of this product should be based on system operating conditions, considering water production, system pressure difference, and desalination rate.

2. Our company can provide cleaning plans based on operating conditions, and the usage and dosage of the cleaner can refer to the corresponding technical plan.

3. The concentration and application temperature of the cleaning solution depend on the type and amount of system deposits. Under the guidance of the cleaning plan, the typical dilution ratio is 1-3% of the entire cleaning system volume (usually 1:45), including the cleaning tank, connecting pipes, filters, pressure vessels, and membranes.

View MoreProduct Code SM-3210S

Appearance Transparent and homogeneous amber-coloured liquid

Proportion 1.10~1.20

pH value (1% aqueous solution) 1.0~3.0

-

BENEFITS & FEATURES

1. The use of the RO membrane-specific alkaline cleaner should be based on system operating conditions, considering water production, system pressure difference, and desalination rate.

2. Our company can provide cleaning plans based on operating conditions, and the usage and dosage of the cleaner can refer to the corresponding technical plan.

3. The concentration and application temperature of the cleaning solution depend on the type and amount of system deposits. Under the guidance of the cleaning plan, the typical dilution ratio is 1-3% of the entire cleaning system volume (usually 1:45), including the cleaning tank, connecting pipes, filters, pressure vessels, and membranes.

View MoreProduct Code SM-3210J

Appearance Transparent and homogeneous amber-coloured liquid

Proportion 1.10~1.20

pH value (1% aqueous solution) 10.0~13.0

Since 1991

Changzhou SanmingJingHui Environmental Protection Technology Co., Ltd.

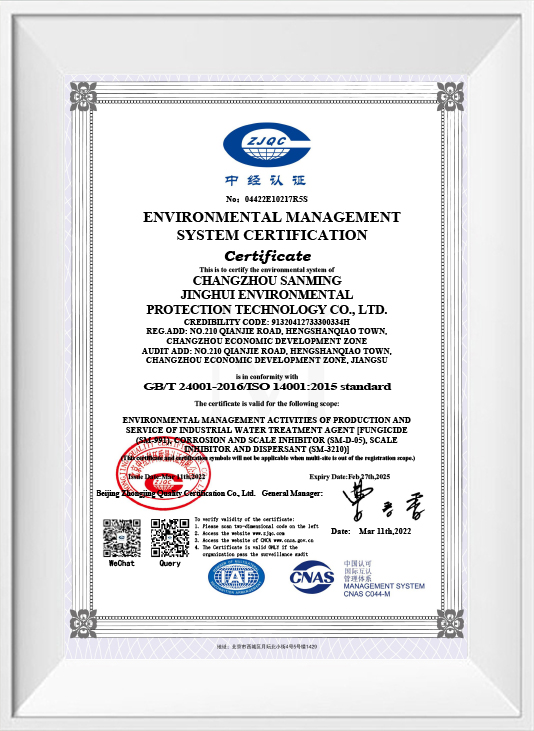

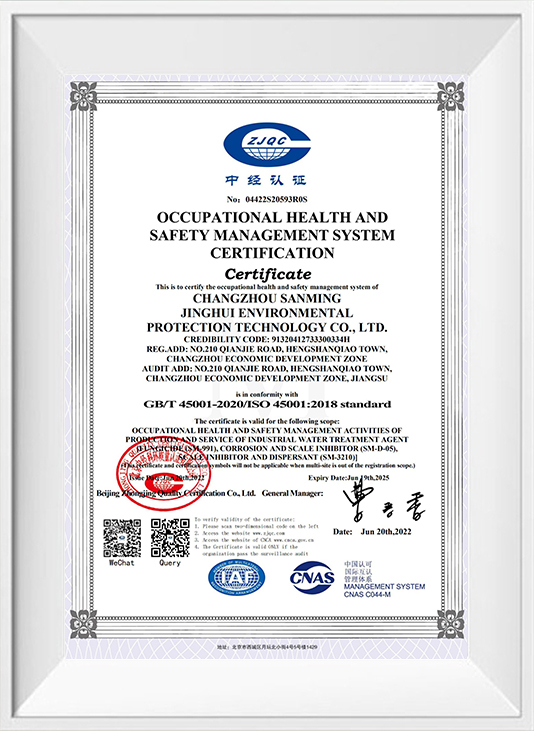

Changzhou SanmingJingHui Environmental Protection Technology Co., Ltd. (formerly Changzhou Sanming Chemical Co., Ltd.) is China reverse osmosis chemicals manufacturers and slime stripping agent factory, a high-tech, environmentally friendly and energy-saving water treatment agent professional enterprise integrating scientific research and development, production and sales, and technical services. It was founded in 1991.

The company is located in the central area of the Yangtze River Delta, close to the Shanghai-Nanjing Railway and the Beijing-Hangzhou Grand Canal, and is located in Hengshanqiao Town, the middle intersection of the Shanghai-Nanjing Expressway. It is only half an hour away from Changzhou Civil Aviation Airport and has convenient transportation. It has fixed assets of more than 18 million yuan, more than 20 scientific researchers, and 25% of employees have obtained various professional and technical titles.

-

Essential Dosing Strategies for Maximum Efficiency Proper dosing of boiler treatment chemicals is critical for protecting your system while avoiding waste. Mos...

READ MORE -

Essential Water Treatment Chemicals and Their Applications Water treatment relies on specific chemicals to remove contaminants, kill pathogens, and ensure safe...

READ MORE -

Poly aluminium chloride (PAC) is a fast, robust coagulant for water treatment that typically improves turbidity and color removal with steadier pH than alum—whe...

READ MORE -

Most industrial wastewater can be brought into stable compliance by pairing the right coagulant + polymer with tight pH control, then verifying doses with jar t...

READ MORE

More product information about Reverse Osmosis Water Treatment System

Why Is Antiscalant Added in Reverse Osmosis Equipment?

Before discussing the role of antiscalants in reverse osmosis systems, let’s first understand the process:

Reverse osmosis (RO) water treatment involves multiple filtration stages, including precision filters and activated carbon filters, followed by pressurization and passage through an RO membrane with a pore size of 1/10,000 μm. This membrane separates impurities like industrial pollutants, heavy metals, bacteria, and viruses, transforming higher-concentration water into purified, low-concentration water that meets drinking standards. RO technology offers the highest water purity of all known water treatment methods, almost reaching 100% purity.

The RO membrane is critical in the system. Over time, calcium and magnesium ions in the water precipitate and attach to the membrane, forming scale that clogs the pores. This reduces water production efficiency and damages the membrane. To protect the membrane, an additional chemical dosing system is used to add antiscalant, preventing scale formation and improving system efficiency.

Our RO antiscalant is specifically designed for use in RO, nanofiltration (NF), and ultrafiltration (UF) systems. It prevents membrane fouling, enhances water production, and reduces operational costs.

Features

- Controls inorganic scaling effectively across a wide concentration range.

- Does not form insoluble compounds with iron, aluminum oxides, or silica.

- Inhibits silica polymerization and deposition, with SiO2 concentrations up to 290 ppm.

- Compatible with RO CA and TFC membranes, NF membranes, and UF membranes.

- Excellent solubility and stability.

- Effective in a water pH range of 5-10.

Antiscalant Functions

-

Chelating and Solubilizing Effect: The antiscalant forms negatively charged chains that combine with Ca2+ ions, increasing the solubility of inorganic salts and preventing scaling.

-

Lattice Distortion: Functional groups in the antiscalant molecules attach to crystal nuclei, disrupting crystal growth and reducing scale formation.

-

Electrostatic Repulsion: The antiscalant adsorbs on salt microcrystals, increasing repulsion between particles and preventing aggregation, which helps keep salts in a dispersed state.

-

Scale Prevention: Antiscalants and dispersants prevent mineral salt precipitation and scale formation.

Applications of RO Antiscalants

-

Polyacrylic Acid-Based Antiscalants: Caution is needed with high iron content as it may cause membrane fouling, which requires acid cleaning.

-

Cationic Coagulants in Pretreatment: Be cautious when using anionic antiscalants, as they may cause sticky contamination, increasing operating pressure and making cleaning difficult.

-

Prevents Salt Crystallization: Antiscalants allow salts to exceed their saturation limits in the concentrate without crystallizing. They can replace or complement acid dosing.

-

Dosing Amount: The ideal dosage should be determined using specialized software from the supplier. Overdosing can lead to new fouling problems, so the system must be properly flushed during downtime.

-

Injection System Design: Ensure thorough mixing of antiscalants and dispersants before reaching the RO membranes. Static mixers are highly effective for this purpose.

-

Dosing Pump: Set the pump to the highest injection rate, typically dosing at 2-5 ppm. Diluted antiscalants should be used within 7-10 days to prevent biological contamination. Antiscalants must be compatible with the RO membrane to avoid irreversible damage.

En

En

عربى

عربى 中文简体

中文简体